We changed our shelter system when our baby Lil’ Flier was born in anticipation for our PCT LASH with two kids under 5 years old.

As part of that shelter system, we rely on a bathtub floor to keep the kids clean, dry and off the ground.

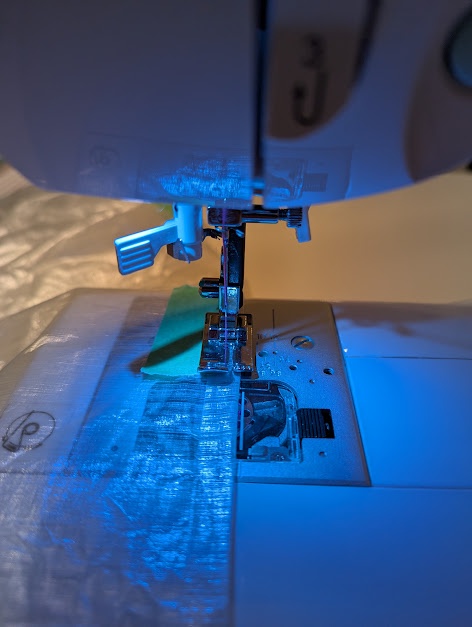

I made the bathtub floor myself in my living room and on our dining table using our domestic sewing machine. This was the first time I ever made anything with DCF.

Materials

- 0.67 DCF CT1E.08/K.18 and chose clear for the cost.

- I own DCF gear but have never worked with it to make something (other than DCF repair patches)

- I know that DCF isn’t the most abrasion resistant choice, and this might be a bit light duty. I hope to use site selection to limit pinholes. I truly contemplated using something heavier (eg: 1.1 silpoly or something) but want to go as light as feasible on the floor.

- Gutermann MARA 70 thread. Fuscia. Makes edges and features easier to see on the clear DCF.

- We have a domestic machine – Singer 7258

- Microtex 90/14 needles

- 0.5 DCF one sided tape from Dutchware

- 1/4″ Grosgrain for corner loops

- Yogurt containers

Design

I modelled the tent in Solidworks and came up with a design for the bathtub there as well.

I chose to use a 3/4 design to get more floor space while still being able to use one of the doors to prevent rain infiltration.

I prototyped as much as possible. I made a pattern or lay out in CAD and updated the dimensions as I prototyped. I used polycro as a physical prototype.

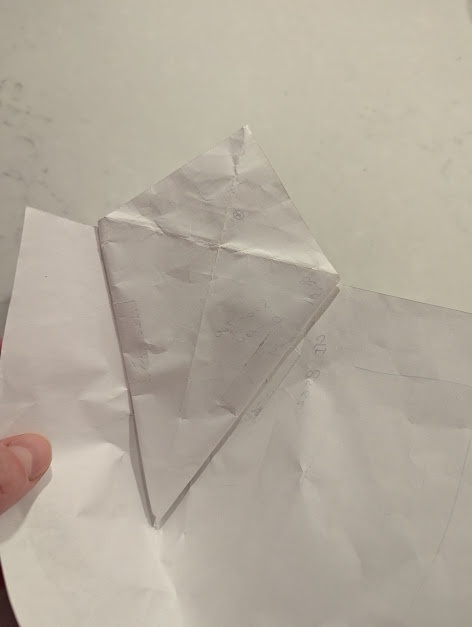

The general design is simple. What was a bit different from what I could find online was how I handled the corners. I folded the corners, but pulled the triangle of fabric inwards and sewed a straight stitch. Then taped the outside. That left a triangular pocket, which I slid a piece of plastic from a yogurt container in as a corner stiffener. I sewed a 1/4 grossgrain to that – the grossgrain loops on the corners pull on the plastic, not on DCF.

This seems to keep the stress off of the DCF and the entire setup, once taped, should be quite water proof since there is one seam that’s easily taped up.

I had to connect two pieces of DCF together to get the width. I sewed them together with a straight stitch and then taped the seam on bottom and top.

Result

It fits well in the tent, and our gear fits the floor, but I could have made is a couple inches larger. I over compensated when reacting to the prototype.

The floor is 136 grams total.

The corners hold themselves vertical quite well.

2 thoughts on “MYOG tent bathtub floor”